Researchers from MIT have developed a new sodium-based fuel cell that could significantly impact the future of electric transportation, particularly in aviation. Designed to deliver over three times the energy density of today’s lithium-ion batteries, this fuel cell could offer a practical, lightweight alternative for powering aircraft, heavy-duty vehicles, ships, and trains.

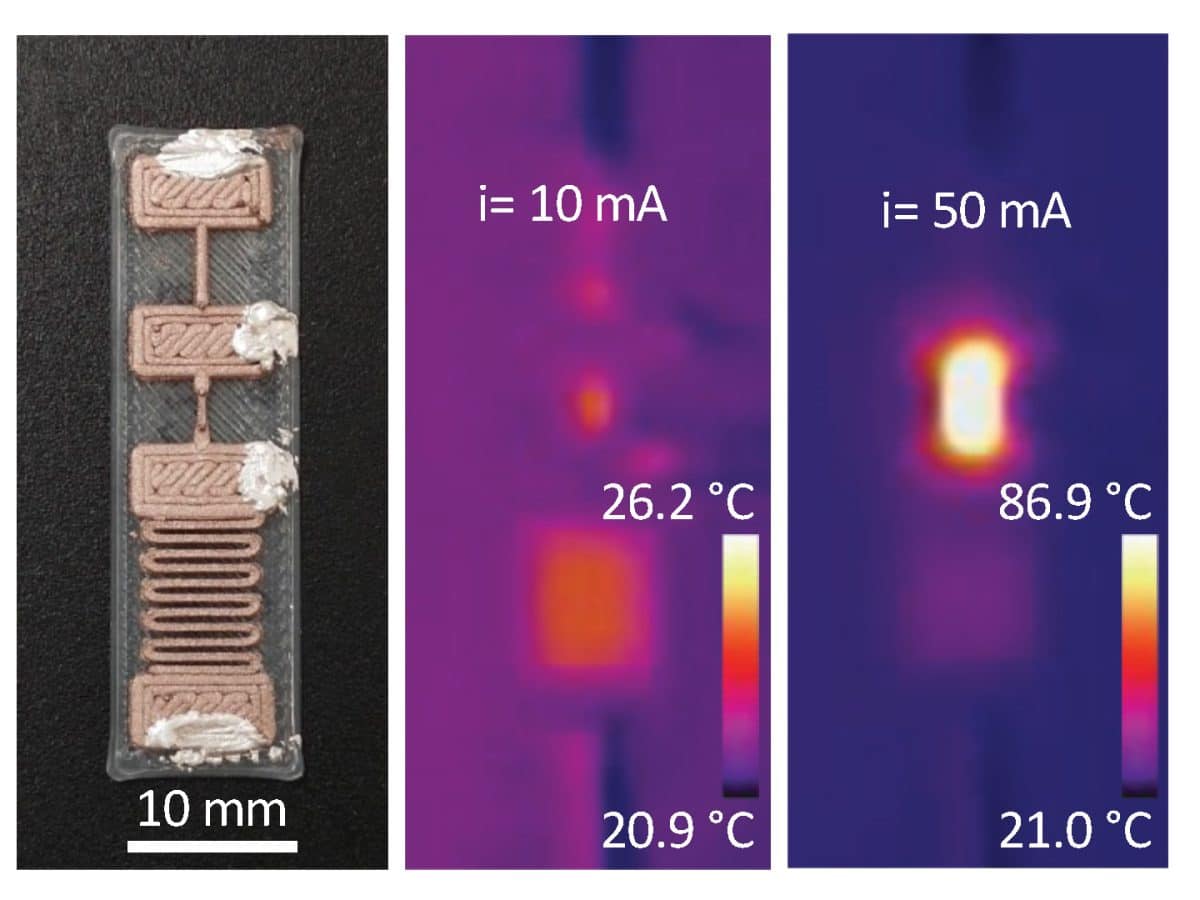

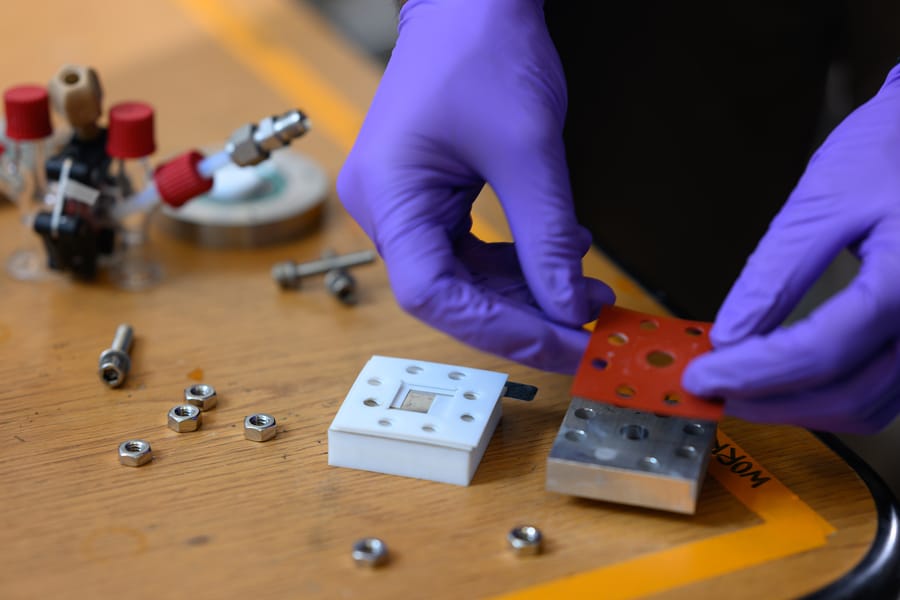

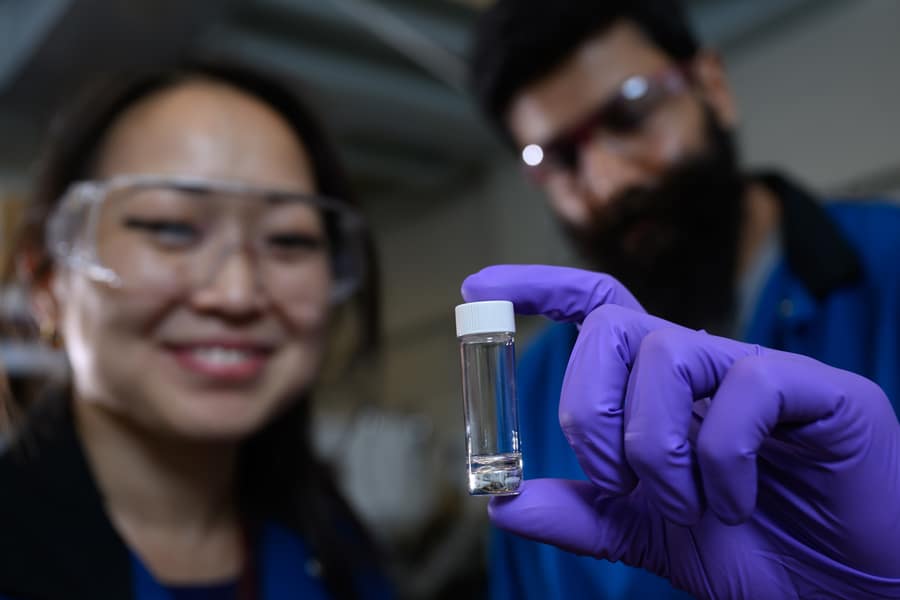

Unlike conventional batteries that store energy and are sealed units, fuel cells work by introducing external fuel to generate electricity. The new concept developed by a team of researchers at MIT and other institutions uses liquid sodium metal as fuel, paired with atmospheric oxygen. A solid ceramic electrolyte allows sodium ions to travel between the fuel and air, while a porous electrode supports the chemical reaction that produces electricity.

Credits: Credit: Gretchen Ertl

Initial tests of the prototype demonstrated energy densities exceeding 1,500 watt-hours per kilogram at the cell stack level. This surpasses the 300 watt-hours per kilogram found in today’s lithium-ion batteries and crosses the critical 1,000 watt-hours per kilogram threshold needed for regional electric aviation. The researchers suggest this could enable electric flights covering short-to-medium distances, which represent the bulk of domestic air travel and contribute significantly to aviation emissions.

The fuel cell design offers additional benefits. It produces sodium oxide as a byproduct, which reacts with moisture and carbon dioxide in the air to eventually form baking soda. This natural process could help absorb carbon dioxide from the atmosphere, offering a potential carbon capture benefit during operation. If the byproducts reach the ocean, they could also help neutralise acidity, addressing another major environmental concern.

Credits: Credit: Gretchen Ertl

Researchers have built two lab-scale prototypes of the cell, one with a vertical configuration and the other horizontal. Both designs demonstrated the feasibility of sustained energy generation using sodium metal and humidified air. The team envisions a modular cartridge system for future use, with sodium fuel cells loaded into aircraft and replaced at refuelling stations when depleted. Sodium’s abundance and historical use at large industrial scales support the viability of this supply chain.

Safety, always a concern with high-energy systems, is also addressed in the fuel cell design. Sodium metal is reactive, but the cell structure keeps one side open to air, avoiding the storage of two concentrated reactive materials together — reducing the risk of runaway reactions common in some battery failures.

Credits: Credit: Gretchen Ertl

The team behind the discovery has founded a startup, Propel Aero, to scale the technology and explore commercial applications. The initial aim is to build a small brick-sized fuel cell to power large drones, a proof of concept that could be used in agriculture and other industries.

Beyond aviation, the sodium fuel cell system could power marine and rail transport, both of which require high energy density and lower-cost alternatives to traditional fuels. Because sodium is derived from salt and is widely available, this approach could be more scalable than lithium-based systems, which rely on rarer and more expensive materials.

If successful at scale, this innovation could play a key role in advancing clean, electrified mobility across multiple sectors, aligning with broader sustainability goals and net-zero ambitions. The system’s ability to combine high energy output, low material cost, and environmental benefits could make it a strong contender in the next wave of transportation technology.