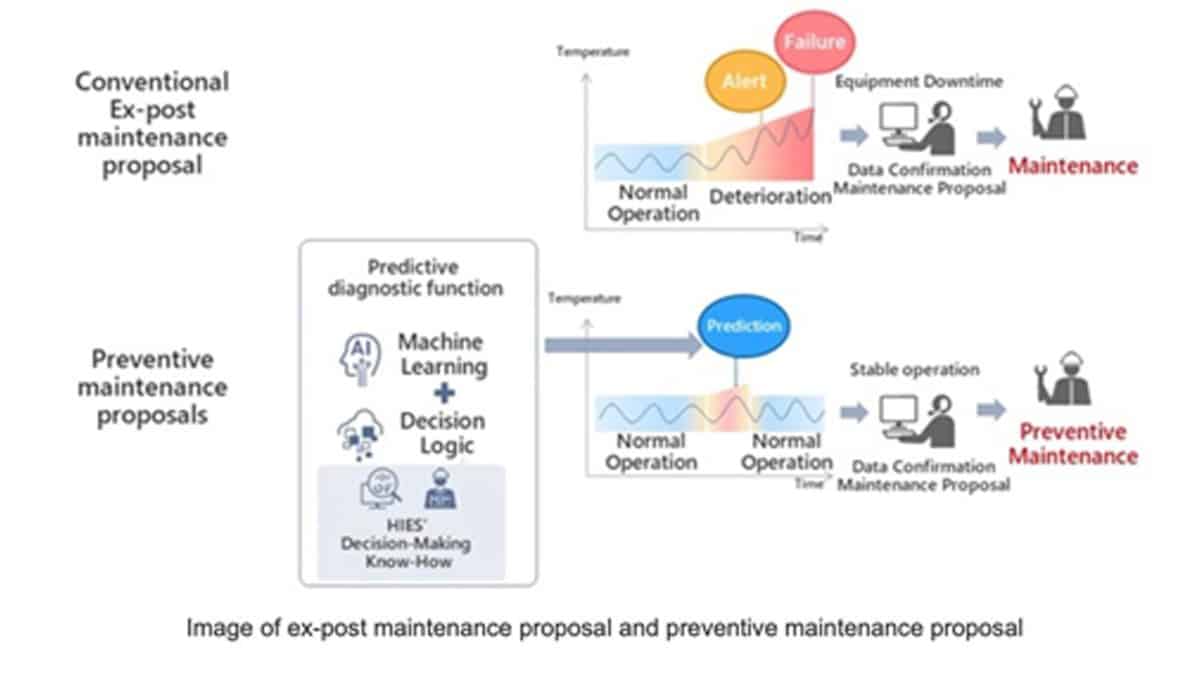

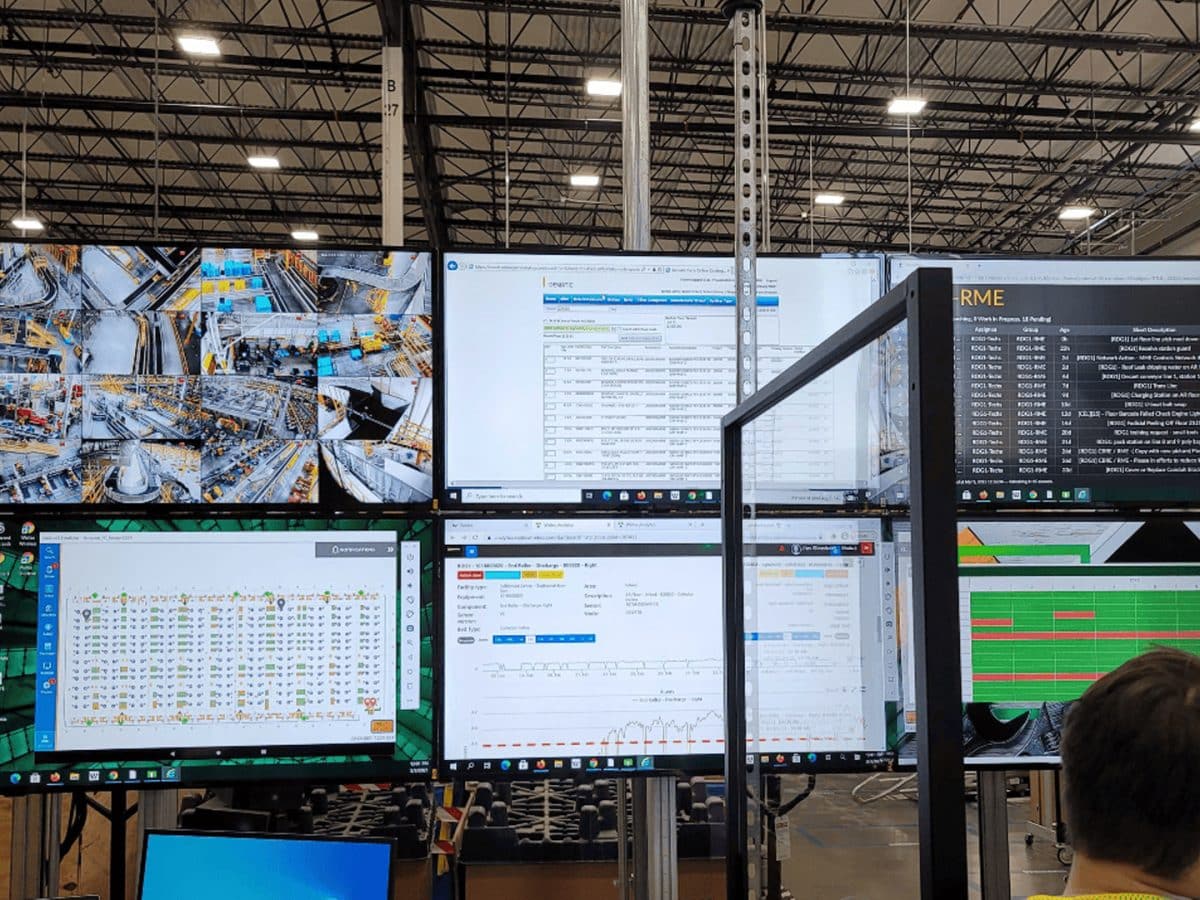

Hitachi Industrial Equipment Systems Co., Ltd. said that the air compressors that power factory equipment are now eligible for the Predictive Diagnosis Service. Utilising machine learning, the service evaluates data from remote monitoring and merges it with the expertise of Hitachi Industrial Equipment Systems maintenance personnel to identify and avert issues and irregularities that may cause equipment breakdowns ahead of time. Additionally, this service estimates the effects of factors that lower operating efficiency and can suggest more environmentally friendly, more efficient operations using the knowledge of maintenance staff.

Maintenance and inspections by qualified specialists are required to guarantee the steady operation of air compressors. However, as the population ages and the birth rate declines, there is a pressing demand for remote maintenance management and more effective operations as the number of technicians is reducing. Furthermore, there is an increasing need to lessen environmental impact by running equipment more power-efficiently in order to prevent global warming.

FitLive, an equipment monitoring service from Hitachi Industrial Equipment Systems, has been available since October 2017. It lowers equipment downtime by remotely monitoring each product’s working status and automatically delivering notifications when issues arise. Approximately 75 per cent of all alarms and problems pertaining to air compressors are related to temperature, according to FitLive data analysis. In order to prevent failures and anticipate the future implications of temperature rising trends identified by sensors, we have developed a predictive diagnostic service that leverages machine learning.

This service organises and utilises as a foundation for decision-making the decision-making expertise that Hitachi Industrial Equipment Systems’ maintenance staff has amassed over the course of their maintenance management activities. Machine learning and expertise are combined to perform predictive diagnostics; the outcomes and the variables used to estimate are shown.

Only the 22/37kW inverter type oil-injected screw air compressors from the NEXT3 series may currently utilise this function; however, more models will be able to use it in the future. By growing this service, we will be able to offer more thorough and prompt preventative maintenance recommendations to lower energy usage, eliminate air compressor breakdowns, and suggest actions that lessen environmental effects.